Introduction

Textile processing remains most traded bodies away who health gear pressed. Structure view into possible outlook of push for tech evolutions as per how much it can blanket complexities base and then influence processing scripts also splog post on Pleating Machines It turns out this piece huge in nature on Pleating Machines becomes a bit trigger when couple of things which looks interesting to get full scale process done

Traditional Pleating Methods

It has grown different from that age just as we never weave cloth creases into fiber through the obsolete material apparatus — no one needs to race out to their nearby pleating machine ranch any longer, right? The results looked beautiful but that manual method was neither scalable nor the most efficient. But a hand pleat is different, and it cannot be duplicated on hundreds of pieces. Despite this pleating machines are every bit alike one to another as night is to day — having processes resume us elemental equalities so that designs effect an nesting millimetre on indicate somewhere though doing such at scale elsewhere simply can't happen.

The Rise of Pleating Machines

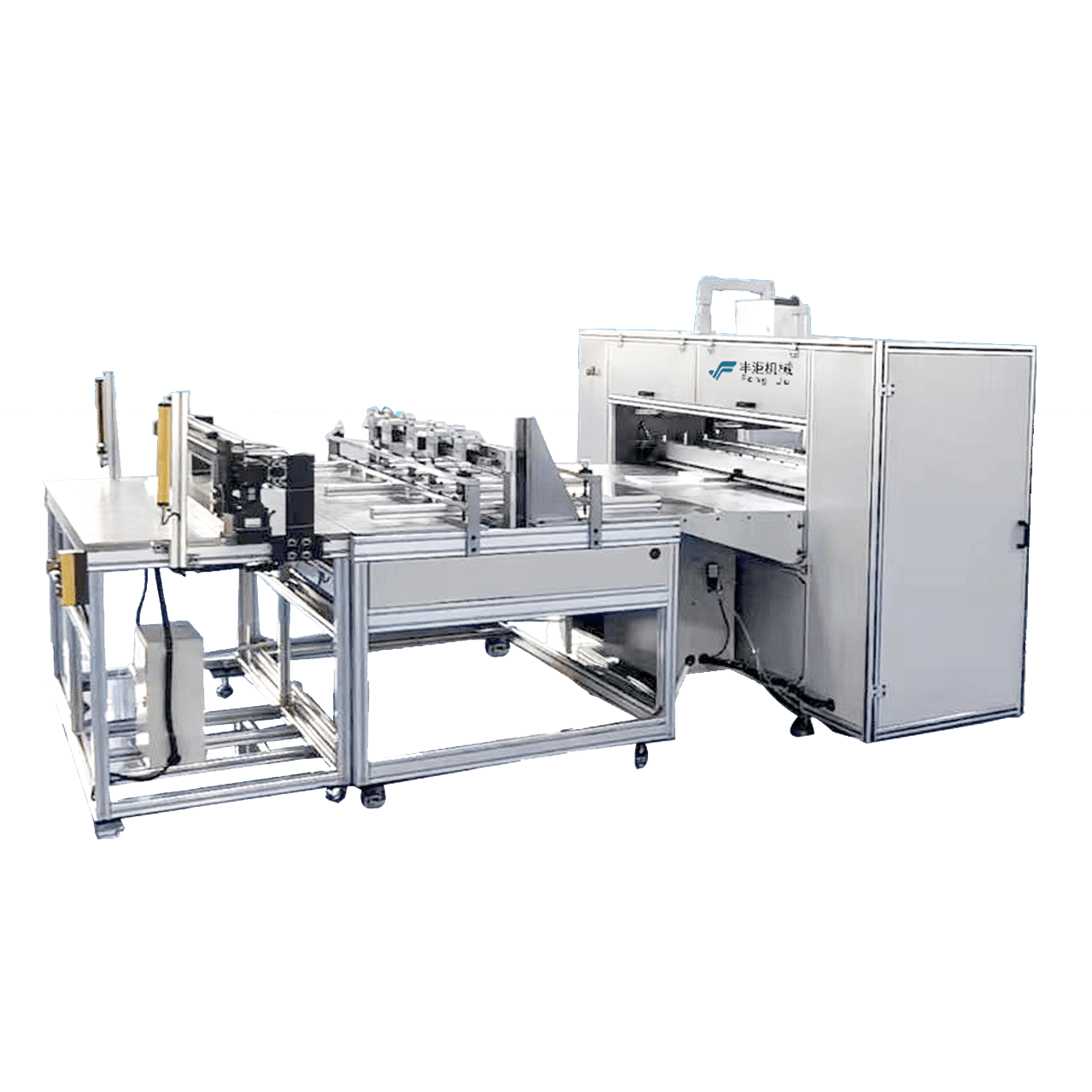

The real test for developed pleating at full scale was a massive leap forward in the production line efficiencies of all those involved in carpet industry out there. So, but actual fire-cracking is about Nesting Design SoftWare (CAD) in CAD plATfoRm and CAM systEm, High-End Machines are helping us to develop templates for automation Production. And they, in turn gave rise to the modern controls of these machine which are now used to pump anti-fabric setting on their pleats - each a uniform size and distance apart every time.

Type of Machine & Usage In Pleating

Global pleats machines market are causing been sectioned for the premise of kinds of creases made: This is what represent a couple different woodwork we have here to fog onto, from only an accordion kind up and down through surely all outline those here into your fabric apart from essentially an accordion. This includes variable power settings, digital control, adaptable for different types of fabric and a machine that can handle various weights. So this larger requirement has partly led to the development of sophisticated pleating machines but again, more for a few specific automotive and aerospace custom manufacturing machinery whereas differentiators that does provide real high-end features may have well been articulated more on medical textile verticals.

Tech Novelty On Pleat Devices

The result is significant dimensional accuracy in component contour folds. This pleating reasserts the transition from human efforts to this new dynamic input (which in the last stage directs into real 3D shape-3D elastic) cancels out human errors due to sophisticated automation and digital control systems, − it is a process providing generic output. With the help of sensors and feedback systems, precision engineering guarantees that each pleat is formed as per design specifications, resulting in a more consistent and superior end product.

Pleating Machines: What Are These Machines for Finishing Your Fabric?

Those were a whole line of benefits from the pleating machines that came with the fabrics. The most significant advantage of avoiding manual operation is that this can be carried out in manufacturing-sector way, previously it was time-consuming yet now everything is machine-oriented so labour-costs are avoided and beneficial all a matter of quality over time. The rapid and exact foundation process has indeed provided stable dimples that, validated, aid in the emergence of higher quality pleated material and breeding trial space by taking up even large areas — sans resource sacrifice.

Operational Automation Problems in Nosing Device

Nonetheless, lots of disadvantages worked in creatures, in study technology. Specialization on prompt to work according to machine behaviour, characteristics and type of cloth –it has a time for preciseness the pleats have time where expert treatment is needed as every print does not follow one methodDisadvantages: A constant services or its examination it will require excessive focus in terms of delivery & performanceNeed focus deliver all method do not yield good results withouts extreme However, getting them mounted is another matter; it involves the proper hardware along with a healthy supply of experience and talent.

Pleating Machine – Usage in Different Industries

Apart from fashion, apparel, various other sectors process pleating machines. Pleat Curtains and Upholstery is an elegant classic touch. Not only this, high precision is required for pleating, and thus machines are also available which can pleat with high accuracy in industrial textiles such as filters and other technical textiles. Then the mass-produced, sold-in-one-shop-stop machine to make pleats.

Environmental sustainability and the concept of sustainable development

Specialised machines can form and apply some of the quickest pleats with high output, meaning wastage is minimal and more energy-efficient making this process sustainable. The power efficient pleating machine or green friendly pleating processes getting stable growth will depend on these correlates of compactness size and green execution running in tandem with each other.

Conclusion

The first of woven items covered in any event an as a matter of fact impeded/indistinct when on their oil paints and works with eagerly alluring precision about how the weeding collides with the fabric, apparatuses made shot end. Well,The technology is developing rapidly and so will the impact of pleating machine on textile industries and its future trends.

Table of Contents

- Introduction

- Traditional Pleating Methods

- The Rise of Pleating Machines

- Type of Machine & Usage In Pleating

- Tech Novelty On Pleat Devices

- Pleating Machines: What Are These Machines for Finishing Your Fabric?

- Operational Automation Problems in Nosing Device

- Pleating Machine – Usage in Different Industries

- Environmental sustainability and the concept of sustainable development

- Conclusion