Sélection des matériaux

Choisir les bons matériaux joue un rôle crucial dans l'atteinte de l'efficacité dans le plissage de mailles de fenêtre. Des options durables et légères comme le polyester ou la fibre de verre garantissent une manipulation fluide et des résultats durables. Le polyester offre flexibilité et résistance à l'usure, ce qui le rend idéal pour une utilisation fréquente. La fibre de verre, en revanche, fournit force et stabilité, ce qui est essentiel pour maintenir la structure des plis.

Les matériaux de maille résistants à la rouille et à la déchirure améliorent encore la longévité de vos écrans plissés. La maille résistante à la rouille empêche la dégradation causée par l'humidité, garantissant que l'écran reste fonctionnel dans divers environnements. La maille résistante à la déchirure réduit les risques de dommages lors de l'installation ou de l'utilisation quotidienne, vous faisant gagner du temps et des efforts en réparations ou remplacements.

Outils et Équipement

L'utilisation des bons outils et équipements améliore considérablement votre flux de travail. Les outils manuels essentiels, tels que les planches à plis et les pinces, vous aident à créer des plis précis avec un minimum d'effort. Les planches à plis fournissent une surface stable pour le pliage, tandis que les pinces maintiennent le matériau en place de manière sécurisée, empêchant tout glissement pendant le processus.

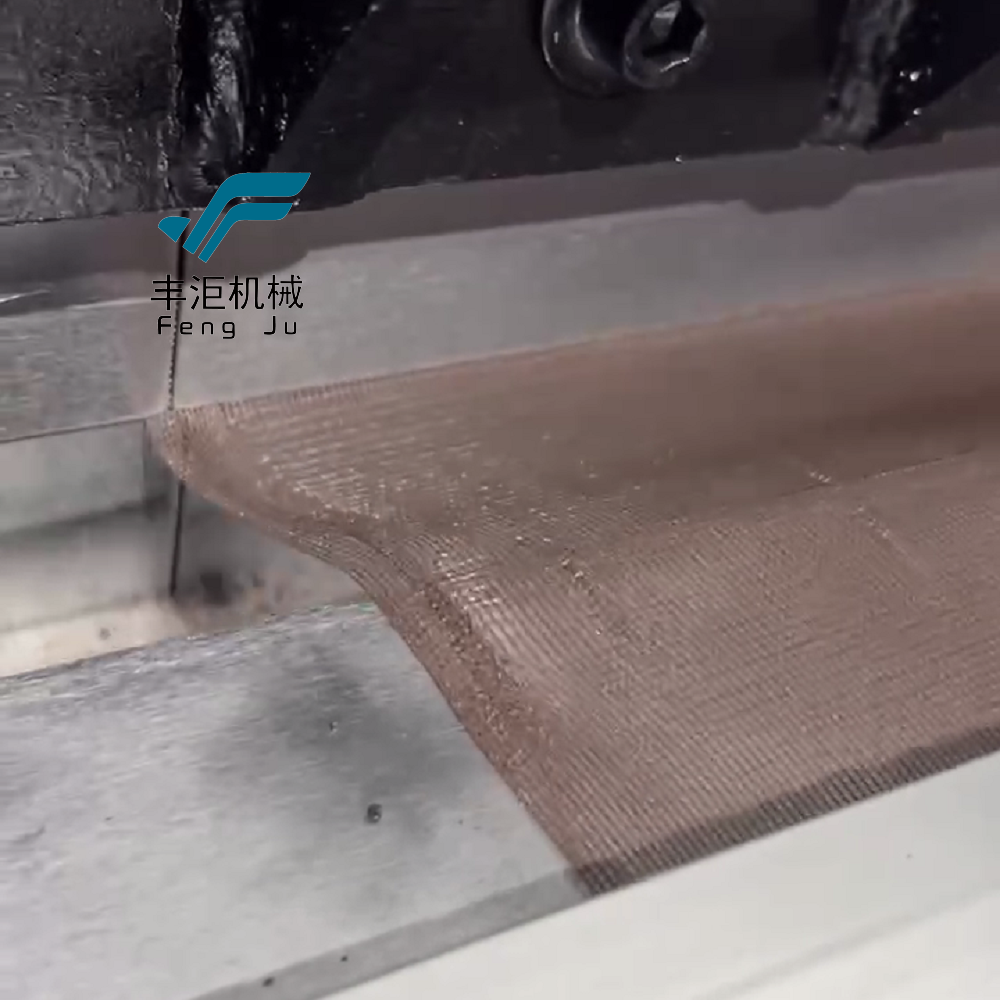

Pour une efficacité avancée, envisagez d'investir dans des machines à plis. Ces machines offrent précision et rapidité, ce qui les rend idéales pour des projets à grande échelle. Elles automatisent les tâches répétitives, vous permettant de vous concentrer sur le contrôle de la qualité et d'autres aspects critiques du processus. En intégrant des équipements avancés, vous pouvez obtenir des résultats cohérents tout en réduisant le temps consacré à chaque projet.

Configuration de l'espace de travail

Un espace de travail organisé est essentiel pour maintenir l'efficacité dans le plissage de mailles de fenêtre. Disposez vos outils et matériaux de manière à minimiser les mouvements inutiles. Gardez les objets fréquemment utilisés à portée de main pour rationaliser votre flux de travail. Un espace de travail dégagé non seulement fait gagner du temps mais réduit également le risque d'erreurs.

Un bon éclairage et une ventilation adéquate sont tout aussi importants. Un éclairage suffisant garantit que vous pouvez voir clairement les détails fins, ce qui est essentiel pour la précision. La ventilation maintient l'environnement confortable, vous permettant de travailler efficacement sans distractions. Un espace de travail bien préparé pose les bases d'un processus de plissage fluide et productif.

Techniques pour un plissage efficace de mailles de fenêtre

Optimisation du processus étape par étape

Diviser le processus de plissage en étapes gérables vous aide à rester concentré et à obtenir des résultats cohérents. Commencez par préparer vos matériaux et outils. Disposez tout ce dont vous avez besoin avant de commencer. Cette préparation minimise les interruptions et maintient votre flux de travail fluide. Ensuite, pliez le maillage de manière systématique, en veillant à ce que chaque pli soit parfaitement aligné. Travaillez sur une section à la fois pour éviter les erreurs. Enfin, fixez fermement les plis à l'aide de pinces ou d'autres outils pour maintenir leur forme.

Rationaliser les tâches répétitives fait gagner du temps et des efforts. Par exemple, si vous devez plisser plusieurs écrans, terminez une tâche, comme couper le maillage, pour tous les écrans avant de passer à l'étape suivante. Cette approche réduit le temps passé à passer d'une tâche à l'autre et améliore l'efficacité globale dans le plissage de maillage de fenêtre.

Conseils pour gagner du temps

La pré-mesure et la découpe des matériaux à l'avance accélèrent le processus de plissage. Utilisez un mètre ruban pour marquer avec précision les dimensions de votre maille. Coupez toutes les pièces à la taille avant de commencer le plissage. Cette préparation élimine les retards causés par l'arrêt pour mesurer et couper pendant le processus.

Les gabarits ou guides garantissent des plis cohérents. Créez un gabarit avec la largeur de pli souhaitée et utilisez-le comme référence lors du pliage. Cette méthode garantit l'uniformité de tous les plis, réduisant ainsi le besoin d'ajustements ultérieurs. La cohérence améliore non seulement l'apparence de votre maille plissée, mais améliore également sa fonctionnalité.

Éviter les erreurs courantes

Prévenir des problèmes comme des plis inégaux ou des déchirures de matériau nécessite une attention aux détails. Vérifiez toujours l'alignement de vos plis au fur et à mesure que vous travaillez. Utilisez des pinces ou des poids pour maintenir la maille en place et éviter tout déplacement. Pour éviter les déchirures, manipulez la maille avec précaution et évitez d'appliquer une force excessive lors du pliage.

Des techniques de dépannage rapides vous aident à résoudre efficacement les erreurs courantes. Si vous remarquez des plis inégaux, dépliez la section affectée et réalignez-la soigneusement. Pour les déchirures mineures, utilisez un adhésif ou un patch pour réparer les dommages sans recommencer. Ces solutions font gagner du temps et garantissent que votre projet reste sur la bonne voie.

Stratégies avancées pour l'efficacité dans le plissage de mailles de fenêtre

Automatisation et technologie

Avantages des machines à plisser pour les opérations à grande échelle

Les machines à plisser révolutionnent les opérations à grande échelle en offrant rapidité et précision. Ces machines gèrent des tâches répétitives avec une précision constante, réduisant le temps que vous passez sur le travail manuel. Elles vous permettent de produire des plis uniformes, ce qui améliore la qualité globale de votre travail. Pour les entreprises ou les particuliers gérant plusieurs projets, les machines à plisser garantissent que vous respectez les délais sans compromettre les résultats. En automatisant le processus de plissage, vous pouvez vous concentrer sur d'autres aspects critiques, tels que la préparation des matériaux ou les contrôles de qualité.

Intégrer l'automatisation dans votre flux de travail pour la cohérence

L'automatisation apporte de la cohérence à votre flux de travail. Lorsque vous intégrez des outils automatisés, vous éliminez les variations causées par l'erreur humaine. Cela garantit que chaque pli répond au même haut standard. Commencez par identifier les tâches qui consomment le plus de temps ou nécessitent des actions répétitives. Introduisez des machines ou des outils capables d'effectuer ces tâches de manière efficace. Par exemple, des coupeurs automatisés peuvent préparer les matériaux plus rapidement, tandis que des machines à plier gèrent le pliage avec précision. L'automatisation non seulement fait gagner du temps, mais renforce également votre confiance dans la livraison de résultats fiables.

Mesures de contrôle qualité

Inspecter les plis pour l'uniformité et la durabilité

Inspecter vos plis garantit qu'ils répondent aux normes requises en matière d'uniformité et de durabilité. Vérifiez chaque pli pour un espacement et un alignement uniformes. Des plis inégaux peuvent affecter la fonctionnalité et l'apparence de votre maille de fenêtre. Utilisez vos mains pour détecter d'éventuels points faibles ou incohérences dans le matériau. Des plis durables résistent à une utilisation quotidienne et aux facteurs environnementaux, donc vérifier leur solidité est essentiel. Des inspections régulières vous aident à identifier et à résoudre les problèmes avant qu'ils ne s'aggravent, vous faisant gagner du temps et des ressources à long terme.

Utiliser une liste de contrôle pour maintenir des normes de qualité élevées

Une liste de contrôle simplifie le processus de contrôle de la qualité. Créez une liste de points clés à examiner pendant et après le plissage. Incluez des éléments tels que l'état du matériau, l'alignement des plis et la durabilité globale. Utilisez cette liste de contrôle comme guide pour vous assurer qu'aucun détail n'est négligé. Par exemple, cochez chaque étape au fur et à mesure que vous la complétez, de l'inspection du maillage pour des déchirures à la vérification de la structure finale des plis. Une approche systématique garantit des résultats cohérents et renforce votre engagement envers des normes de haute qualité.

L'efficacité dans le plissage de mailles de fenêtre dépend de votre capacité à choisir les bons matériaux, à utiliser des outils appropriés et à appliquer des techniques efficaces. En vous concentrant sur ces aspects, vous pouvez rationaliser votre flux de travail et obtenir des résultats cohérents et de haute qualité. La mise en œuvre des stratégies discutées permet non seulement de gagner du temps, mais aussi d'améliorer la durabilité et la fonctionnalité de votre maille plissée. Envisagez d'adopter des méthodes avancées comme l'automatisation pour développer vos opérations et améliorer la précision. Ces approches vous permettent de travailler plus intelligemment, garantissant que chaque projet respecte des normes professionnelles tout en maximisant la productivité.