айналымды илеу машинасы

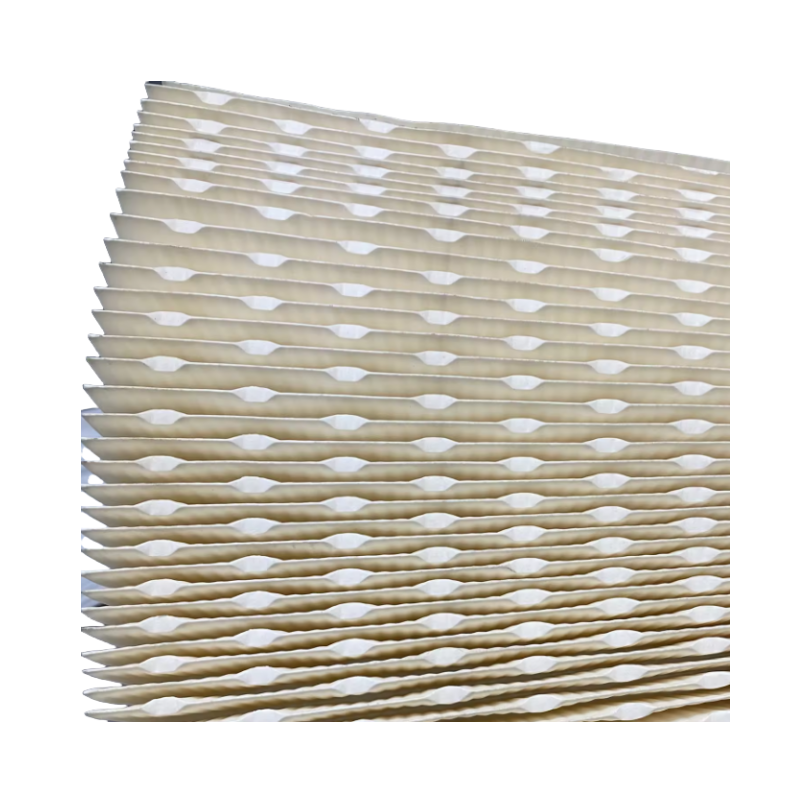

Ротациялық плистеу машинасы әртүрлі материалдарға дәл және біркелкі плистер жасау үшін күрделі шешім ұсынатын, өнеркәсіптік плистеу технологиясының маңызды даму кезеңі болып табылады. Бұл инновациялық жабдық жоғары жылдамдықты өндіруді қамтамасыз ететін, сонымен қатар ерекше плист сапасын сақтайтын үздіксіз ротациялық механизмде жұмыс істейді. Негізінде машина жылу, қысым және механикалық күштің үйлесімі арқылы плистерді қалыптастыратын дәлме-дәл жасалған пышақтары бар айналатын цилиндрлі жүйеден тұрады. Бұл технология материал бойынша оңтайлы жылу таралуын қамтамасыз ететін, уақыт өте қалыптарын сақтайтын, анық, жақсы анықталған плистер алуға мүмкіндік беретін алдыңғы қатарлы температураны бақылау жүйелерін қамтиды. Машина жеңіл мата материалдарынан бастап ауыр маталарға дейінгі кең спектрдегі материалдармен жұмыс істеуге мүмкіндік береді және сондықтан әртүрлі салалардағы кеңінен қолданылуына жарамды. Ерекше сипаттамаларына плистің тереңдігін реттеу, жылдамдықтың өзгермелі бақылауы және оператордың қатысуын минималдандыратын автоматтандырылған материал беру жүйелері жатады. Ротациялық плистеу машинасының үздіксіз жұмыс істеу мүмкіндігі арқылы өнімділікті арттыруға баса назар аударылады және бұл дәстүрлі плистеу әдістерімен салыстырғанда өндіру уақытын ә существенно қысқартады. Қазіргі заманғы нұсқалары жиі әртүрлі плистеу үлгілері мен материал сипаттамалары үшін дәл параметрлерді баптау мен бағдарламаларды сақтау мүмкіндігін беретін сандық басқару интерфейстерін қоса алады.