Mecanism de bază

Mașinile industriale de pliere funcționează printr-un proces simplu, dar eficient. Aceste mașini folosesc sisteme mecanice sau automate pentru a plia țesătura în plii precise. Introduci țesătura în mașină, unde rolele sau lamele o ghidează prin mecanismul de pliere. Mașina aplică presiune și căldură pentru a fixa plii permanent. Acest lucru asigură că plii rămân intacte chiar și după utilizare îndelungată sau spălare.

Mecanismul de bază se bazează pe mișcare constantă și presiune controlată. Poți ajusta setările pentru a crea plii de dimensiuni și modele variate. Această flexibilitate îți permite să personalizezi rezultatul în funcție de nevoile tale specifice. Designul mașinii asigură că fiecare pli este uniform, eliminând inconsistențele care apar adesea în cazul plierii manuale.

Tehnologii cheie

Mașinile industriale de pliere utilizează tehnologii avansate pentru a îmbunătăți eficiența și calitatea. Acestea dispun de controale programabile pentru setări precise, reducând munca manuală. Unele modele folosesc lipirea ultrasonică pentru plii curate în materiale delicate, în timp ce altele au elemente de încălzire pentru pliere consistentă. Senzorii asigură alinierea țesăturii, prevenind erorile, iar modelele multifuncționale permit comutarea ușoară între stilurile de pliere. Aceste inovații fac ca mașinile de pliere să fie versatile pentru diferite aplicații.

Aplicații ale Mașinilor Industriale de Pliere

Industrii care folosesc Mașini de Pliere

Mașinile industriale de pliere joacă un rol vital în mai multe industrii. Sectoarele textile și de modă se bazează în mare măsură pe aceste mașini pentru a crea plii complicate pentru îmbrăcăminte, perdele și tapițerie. Le veți găsi indispensabile în fabricarea articolelor de îmbrăcăminte precum fuste, rochii și bluze care necesită modele de pliere precise. Pagina principală Companiile de decorare folosesc de asemenea aceste mașini pentru a produce draperii pliate și huse pentru perne cu o calitate constantă.

Industria auto beneficiază de mașinile de pliere, de asemenea. Acestea sunt folosite pentru a fabrica filtre pliate pentru sisteme de filtrare a aerului și uleiului. Aceste filtre necesită o precizie ridicată, pe care mașinile industriale de pliere o oferă eficient. În plus, domeniul medical folosește mașini de pliere pentru a produce materiale pliate pentru măști chirurgicale și alte echipamente de protecție. Această versatilitate face ca aceste mașini să fie esențiale în diverse domenii.

Cazuri de utilizare specifice

Mașinile industriale de pliere sunt versatile, utilizate în modă pentru a crea designuri precise și îmbrăcăminte inovatoare, cum ar fi fustele pliate și rochiile. În amenajările interioare, ele asigură uniformitate în perdele și fețe de masă, permițând rezultate profesionale și susținând producția în masă. Aplicațiile tehnice includ producerea de filtre cu dimensiuni exacte pentru mașini și aparate, precum și crearea de materiale nețesute durabile pentru medical și igienă. Produse .

Tipuri de Mașini Industriale de Pliere

Mașinile industriale de pliere vin în diverse tipuri, fiecare fiind proiectată pentru a satisface nevoi specifice. Înțelegerea acestor tipuri te ajută să alegi mașina potrivită pentru aplicația ta. Mai jos sunt cele mai comune tipuri și caracteristicile lor unice.

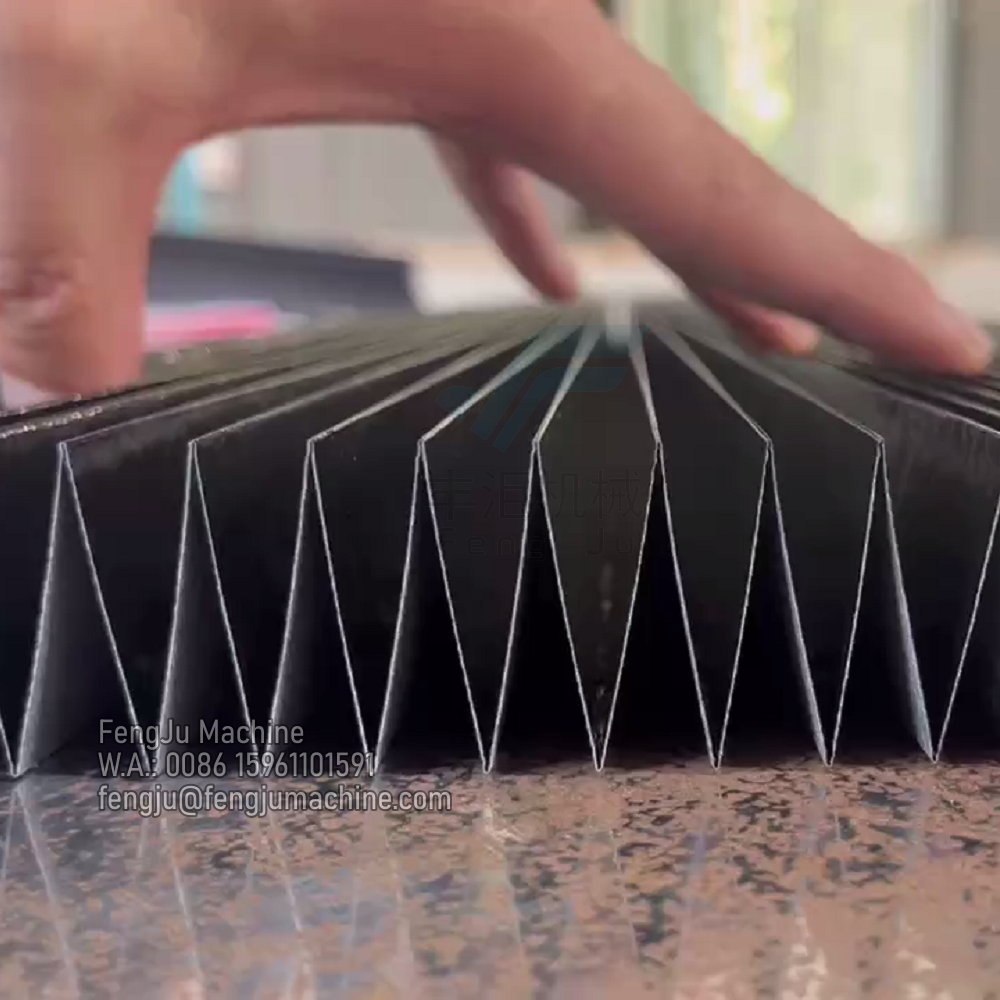

Mașini de pliere cu lamă

Mașinile de pliere cu lamă folosesc lame pentru a plia țesătura în plii precise. Aceste mașini sunt ideale pentru a crea plii ascuțiți și bine definiți. Puteți ajusta setările lamei pentru a produce plii de diferite dimensiuni și modele. Mașina funcționează eficient cu o varietate de materiale, inclusiv țesături sintetice și amestecuri.

Mașinile de pliere cu lamă sunt populare în industria modei. Ele vă ajută să creați fuste pliate, rochii și alte articole vestimentare cu o calitate constantă. Aceste mașini funcționează de asemenea bine pentru articole de decor pentru acasă, cum ar fi perdelele și fețele de masă. Mecanismul lor simplu asigură fiabilitate și ușurință în utilizare.

Mașini de pliere rotativă

Mașinile de pliere rotativă folosesc role rotative pentru a forma plii. Aceste mașini excelează în medii de producție de mare viteză. Puteți conta pe ele pentru a gestiona volume mari de țesătură fără a compromite precizia. Mecanismul rotativ asigură plierea lină și continuă, făcându-le potrivite pentru operațiuni la scară industrială.

Aceste mașini sunt utilizate frecvent în aplicații tehnice. De exemplu, le poți folosi pentru a produce filtre pliate pentru sisteme de filtrare a aerului și uleiului. Mașinile de pliere rotativă susțin, de asemenea, crearea de materiale nețesute pentru produse medicale și de igienă. Viteza și precizia lor le fac un activ valoros în industriile care necesită producție în masă.

Mașini de pliere în cutie

Mașinile de pliere în cutie se specializează în crearea de plii în formă de cutie. Aceste plii adaugă adâncime și textură țesăturilor, făcându-le populare atât în modă, cât și în decorarea casei. Poți folosi aceste mașini pentru a produce modele pliate pentru fuste, bluze și draperii. Designul mașinii asigură uniformitate, chiar și pentru modele complexe.

Mașinile de pliere în cutie oferă versatilitate. Poți ajusta setările pentru a crea plii de lățimi și adâncimi variate. Această flexibilitate îți permite să experimentezi cu diferite stiluri și modele. Aceste mașini sunt prietenoase cu utilizatorul, făcându-le potrivite atât pentru micile afaceri, cât și pentru producătorii de mari dimensiuni.

Mașini personalizabile

Mașinile de pliere personalizabile oferă flexibilitate pentru a ajusta setările și caracteristicile pentru a satisface nevoile specifice de producție. Ele pot modifica modelele de pliere și pot acomoda diverse materiale, asigurând rezultate de calitate. Software-ul avansat permite programarea designurilor de pliere pentru o producție constantă și experimentare creativă.

Ideale pentru afaceri cu proiecte diverse, aceste mașini economisesc spațiu și investiții prin adaptarea la diferite aplicații. Atunci când alegeți, prioritizați interfețele prietenoase cu utilizatorul, construcția robustă și întreținerea ușoară pentru eficiență pe termen lung și adaptabilitate la cerințele industriei.

Beneficiile utilizării mașinilor industriale de pliere

eficiență și productivitate

Mașinile industriale de pliere îmbunătățesc semnificativ eficiența producției dumneavoastră. Aceste mașini automatizează procesul de pliere, reducând timpul necesar pentru finalizarea sarcinilor. Puteți gestiona volume mari de țesătură fără a compromite calitatea. Viteza constantă a acestor mașini asigură că respectați termenele limită stricte cu ușurință.

Prin utilizarea mașinilor industriale de pliere, minimizați munca manuală. Acest lucru permite echipei dumneavoastră să se concentreze pe alte aspecte critice ale producției. Mașinile reduc, de asemenea, timpii de nefuncționare prin menținerea unui flux de lucru constant. Caracteristicile lor avansate, cum ar fi setările programabile, vă permit să optimizați operațiunile pentru un randament maxim. Această eficiență se traduce în productivitate mai mare, ajutând afacerea dumneavoastră să crească.

Precizie și Constanță

Precizia este un avantaj cheie al mașinilor industriale de pliere. Aceste mașini creează plii uniforme, asigurându-se că fiecare piesă respectă aceleași standarde înalte. Puteți conta pe ele pentru a elimina erorile care apar adesea în cazul plierii manuale. Rezultatul este un finisaj impecabil care îmbunătățește calitatea produselor dumneavoastră.

Consistența este la fel de importantă în producția la scară largă. Mașinile industriale de pliere mențin același nivel de precizie pe parcursul procesului. Indiferent dacă lucrați la un singur articol sau la o comandă în vrac, rezultatele rămân constante. Această fiabilitate construiește încredere cu clienții dvs. și întărește reputația brandului dvs.

Cost-Eficiență

Investiția în mașini industriale de pliere poate economisi bani pe termen lung. Aceste mașini reduc necesitatea muncii manuale, scăzând costurile operaționale. De asemenea, economisiți pe risipa de material, deoarece mașinile asigură tăieturi și plieri precise. Această eficiență vă ajută să profitați la maximum de resursele dvs.

Durabilitatea mașinilor industriale de pliere contribuie la eficiența lor economică. Aceste mașini sunt construite pentru a face față unor sarcini grele, minimizând necesitatea reparațiilor sau înlocuirilor frecvente. Alegând mașina potrivită pentru nevoile tale, îți maximizezi rentabilitatea investiției. În timp, economiile depășesc costul inițial de achiziție, făcând aceste mașini o alegere inteligentă pentru afacerea ta.

Considerații Cheie Atunci Când Alegi O Mașină

Compatibilitatea materială

Atunci când selectezi o mașină industrială de pliere, trebuie să iei în considerare tipurile de materiale cu care lucrezi. Diferite mașini gestionează anumite țesături mai bine decât altele. De exemplu, unele mașini excelează cu țesături sintetice, în timp ce altele funcționează bine cu fibre naturale. Ar trebui să evaluezi dacă mașina poate procesa materiale delicate precum mătasea sau țesături rezistente precum pânza.

Verificați specificațiile mașinii pentru a vă asigura că suportă cerințele materialelor dumneavoastră. Mașinile cu setări ajustabile pentru presiune și căldură oferă o flexibilitate mai mare. Aceste caracteristici vă permit să lucrați cu o gamă mai largă de țesături fără a compromite calitatea. Alegând o mașină compatibilă cu materialele dumneavoastră, evitați problemele de producție și obțineți rezultate constante.

Dimensiunea și Capacitatea Mașinii

Dimensiunea și capacitatea mașinii joacă un rol crucial în atingerea obiectivelor dumneavoastră de producție. Trebuie să evaluați spațiul disponibil în facilitățile dumneavoastră înainte de a lua o decizie. Mașinile compacte funcționează bine pentru ateliere mici, în timp ce modelele mai mari se potrivesc operațiunilor la scară industrială. Măsurați întotdeauna spațiul de lucru pentru a vă asigura că mașina se potrivește confortabil.

Capacitatea determină cât de mult material poate gestiona mașina odată. Mașinile cu capacitate mare sunt ideale pentru afaceri cu volume mari de producție. Dacă conduci o operațiune mai mică, o mașină cu capacitate medie poate fi suficientă. Evaluează nevoile tale actuale și viitoare de producție pentru a selecta o mașină care se aliniază cu creșterea afacerii tale.

Mântuire şi durabilitate

Cerințele de întreținere și durabilitatea afectează performanța pe termen lung a mașinii tale de pliere. Mașinile cu design simplu sunt mai ușor de întreținut, economisind timp și efort. Caută modele cu componente accesibile care permit curățarea și repararea rapidă. Întreținerea regulată asigură funcționarea eficientă a mașinii și îi prelungește durata de viață.

Durabilitatea este un alt factor cheie. Mașinile industriale de pliere trebuie să reziste la utilizare intensă fără defecțiuni frecvente. Alegeți o mașină fabricată din materiale de înaltă calitate și susținută de o garanție de încredere. Mașinile durabile reduc timpul de nefuncționare și costurile de reparare, ajutându-vă să mențineți un proces de producție fluid. Investiția într-o mașină robustă asigură o performanță constantă în timp.

Buget și ROI

Atunci când alegeți o mașină industrială de pliere, luați în considerare bugetul dvs. și caracteristicile de care aveți nevoie. Prețurile variază foarte mult, de la sub 5.000 de dolari la peste 50.000 de dolari. Concentrați-vă pe caracteristici care îmbunătățesc eficiența și calitatea produsului. Mașinile cu prețuri mai mari, dotate cu tehnologie avansată, pot economisi bani pe termen lung prin reducerea forței de muncă și a deșeurilor. Calculați ROI-ul pe baza volumului de producție și a economiilor. De asemenea, analizați durabilitatea mașinii, costurile de întreținere, garanțiile și suportul pentru clienți. Pentru creșterea viitoare, selectați o mașină scalabilă care poate să se adapteze la nevoile crescute de producție.

Mașinile industriale de pliere joacă un rol crucial în industrii precum moda și fabricarea tehnică. Ele îmbunătățesc eficiența, precizia și productivitatea, făcându-le indispensabile pentru crearea de produse pliate de înaltă calitate. Selectarea mașinii potrivite asigură că îți îndeplinești nevoile specifice de producție, maximizând în același timp investiția. Evaluează factori precum compatibilitatea materialelor, capacitatea și durabilitatea pentru a lua o decizie informată. Prin alegerea înțeleaptă, poți optimiza operațiunile și obține rezultate consistente care se aliniază cu obiectivele tale de afaceri.