Cơ chế cơ bản

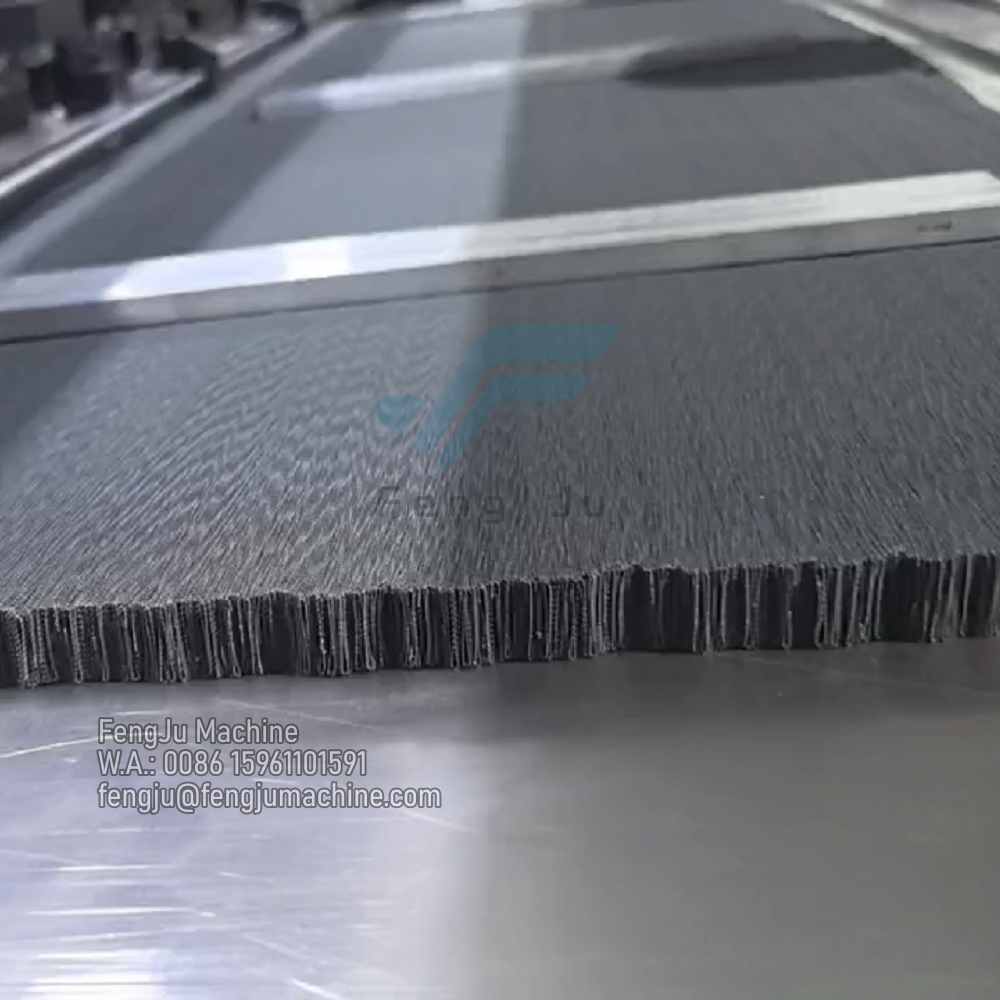

Máy tạo nếp rèm hoạt động bằng cách thao tác vải để tạo ra các nếp gấp đều nhau, được gọi là nếp gấp. Những máy này sử dụng sự kết hợp của các thành phần cơ khí để giữ, gấp và cố định vải vào mẫu nếp gấp mong muốn. Quá trình bắt đầu bằng việc cho vải vào máy. Các con lăn hoặc kẹp giữ vật liệu ở vị trí trong khi cơ chế tạo nếp gấp định hình nó. Khi các nếp gấp được hình thành, máy sẽ cố định chúng bằng cách khâu, ghim hoặc nhiệt, tùy thuộc vào mẫu máy.

Cơ chế cơ bản đảm bảo rằng mỗi nếp gấp đều có kích thước và khoảng cách đồng nhất. Sự nhất quán này rất quan trọng để đạt được vẻ ngoài chuyên nghiệp. Bạn có thể điều chỉnh các cài đặt để tùy chỉnh độ sâu và khoảng cách của nếp gấp, cho phép tạo ra các kiểu khác nhau như nếp gấp kẹp, nếp gấp hộp hoặc nếp gấp ly. Bằng cách hiểu cơ chế này, bạn có thể kiểm soát quá trình tạo nếp gấp và sản xuất ra những kết quả chất lượng cao.

Tự động hóa và chính xác

Các máy xếp nếp rèm hiện đại tích hợp các tính năng tự động hóa tiên tiến để nâng cao độ chính xác và hiệu quả. Các hệ thống tự động loại bỏ nhu cầu điều chỉnh thủ công, giảm thiểu sai sót và tiết kiệm thời gian. Ví dụ, các mẫu máy tính có thể tính toán kích thước và khoảng cách nếp gấp tự động dựa trên thông tin bạn nhập. Điều này đảm bảo rằng mỗi nếp gấp đều thẳng hàng hoàn hảo, ngay cả khi làm việc với các thiết kế rèm lớn hoặc phức tạp.

Tự động hóa cũng cho phép bạn xử lý sản xuất với khối lượng lớn một cách dễ dàng. Các máy được trang bị hệ thống cấp liệu tự động liên tục xử lý vải, giảm thiểu gián đoạn. Một số mẫu máy thậm chí kết hợp xếp nếp với may, cho phép bạn hoàn thành nhiều bước trong một quy trình. Mức độ chính xác và tự động hóa này đảm bảo rằng rèm của bạn duy trì được độ hoàn thiện hoàn hảo và chuyên nghiệp, bất kể kích thước dự án.

Lợi ích của việc sử dụng máy xếp nếp rèm

Hiệu quả và Tiết kiệm thời gian

Máy tạo nếp cho rèm giúp đơn giản hóa quy trình tạo nếp, cho phép bạn hoàn thành công việc trong một khoảng thời gian ngắn hơn nhiều so với việc làm thủ công. Những máy này xử lý các hành động lặp đi lặp lại như gấp và may với tốc độ đáng kinh ngạc. Bạn có thể tập trung vào các khía cạnh khác của dự án trong khi máy đảm bảo kết quả nhất quán. Đối với sản xuất quy mô lớn, hiệu quả này trở nên quý giá hơn nữa. Dù bạn đang làm rèm cho một phòng đơn hay toàn bộ tòa nhà, những máy này giúp bạn đáp ứng thời hạn mà không làm giảm chất lượng.

Độ chính xác và Tính nhất quán

Đạt được nếp gấp đồng đều bằng tay có thể là một thách thức. Máy gấp rèm loại bỏ khó khăn này bằng cách cung cấp kết quả chính xác và nhất quán mỗi lần. Các cơ chế tự động đảm bảo rằng mỗi nếp gấp phù hợp với kích thước chính xác mà bạn đã đặt. Sự chính xác này nâng cao vẻ ngoài tổng thể của rèm cửa của bạn, mang lại cho chúng một hoàn thiện chuyên nghiệp. Bạn có thể tin tưởng vào những chiếc máy này để duy trì độ chính xác, ngay cả khi làm việc với các thiết kế phức tạp hoặc vải mỏng manh. Sự nhất quán trong việc gấp không chỉ cải thiện tính thẩm mỹ mà còn đảm bảo các lợi ích chức năng như sự rủ xuống đều và căn chỉnh đúng cách.

Tính Đa Dạng

Máy tạo nếp rèm thích ứng với nhiều kiểu nếp và loại vải khác nhau, khiến chúng trở thành những công cụ rất linh hoạt. Bạn có thể dễ dàng tạo ra nếp kẹp, nếp hộp hoặc nếp cốc. Nhiều máy cho phép bạn điều chỉnh cài đặt để phù hợp với độ sâu và khoảng cách nếp khác nhau. Sự linh hoạt này cho phép bạn thử nghiệm với các thiết kế và phục vụ sở thích đa dạng của khách hàng. Thêm vào đó, những máy này hoạt động tốt với nhiều loại vật liệu, từ vải mỏng nhẹ đến vải rèm nặng. Sự đa dạng của chúng đảm bảo rằng bạn có thể thực hiện bất kỳ dự án nào với sự tự tin và sáng tạo.

Các loại máy tạo nếp rèm

Máy tạo nếp rèm có nhiều loại khác nhau, mỗi loại được thiết kế để đáp ứng các nhu cầu và sở thích cụ thể. Hiểu rõ các loại này giúp bạn chọn được máy phù hợp cho các dự án của mình. Dù bạn ưu tiên điều khiển thủ công, tự động một phần hay tự động hoàn toàn, luôn có một chiếc máy được thiết kế phù hợp với yêu cầu của bạn.

Máy tạo nếp rèm bán tự động

Máy tạo nếp rèm bán tự động kết hợp giữa đầu vào thủ công và các tính năng tự động. Những máy này đơn giản hóa quy trình tạo nếp bằng cách tự động hóa các công việc lặp đi lặp lại như gấp hoặc may. Bạn vẫn kiểm soát một số khía cạnh, chẳng hạn như vị trí vải hoặc điều chỉnh nếp gấp, nhưng máy sẽ xử lý các bước tốn nhiều công sức hơn.

Máy bán tự động tạo ra sự cân bằng giữa hiệu quả và tùy chỉnh. Chúng phù hợp cho sản xuất quy mô vừa hoặc khi bạn cần kết quả nhất quán mà không hy sinh tính linh hoạt. Nhiều mẫu máy bao gồm các cài đặt có thể điều chỉnh cho độ sâu và khoảng cách nếp gấp, cho phép bạn thử nghiệm với các kiểu dáng khác nhau. Nếu bạn muốn tiết kiệm thời gian trong khi vẫn duy trì một số quyền kiểm soát sáng tạo, máy bán tự động cung cấp một giải pháp thực tế.

Máy tạo nếp rèm hoàn toàn tự động

Máy tạo nếp rèm tự động hoàn toàn mang lại hiệu suất và độ chính xác tối đa. Những máy này xử lý toàn bộ quy trình tạo nếp, từ việc cấp vải đến may hoặc ghim. Các mẫu tiên tiến có hệ thống máy tính tính toán kích thước và khoảng cách nếp tự động. Bạn chỉ cần nhập các cài đặt mong muốn, và máy sẽ làm phần còn lại.

Máy tự động hoàn toàn là lựa chọn hoàn hảo cho sản xuất quy mô lớn hoặc sử dụng thương mại. Chúng đảm bảo các nếp đều đặn với nỗ lực tối thiểu, làm cho chúng trở nên vô giá cho các dự án có khối lượng lớn. Một số mẫu thậm chí tích hợp các chức năng bổ sung, chẳng hạn như cắt hoặc gấp mép, để tối ưu hóa quy trình làm việc hơn nữa. Nếu bạn ưu tiên tốc độ, độ chính xác và năng suất, một máy tự động hoàn toàn là lựa chọn tối ưu.

Những yếu tố chính cần xem xét khi chọn máy tạo nếp rèm

Khi chọn một máy xếp nếp rèm, bạn phải đánh giá nhiều yếu tố để đảm bảo nó phù hợp với nhu cầu của bạn. Mỗi yếu tố đều đóng vai trò quan trọng trong việc xác định sự phù hợp của máy cho các dự án của bạn. Bằng cách đánh giá cẩn thận những khía cạnh này, bạn có thể đưa ra quyết định thông minh và tối đa hóa giá trị của khoản đầu tư của mình.

Ngân sách

Ngân sách của bạn đặt nền tảng cho việc mua sắm. Máy xếp nếp rèm có giá cả rất khác nhau, tùy thuộc vào các tính năng và mức độ tự động hóa của chúng. Các máy thủ công thường có giá cả phải chăng hơn và phục vụ cho các dự án quy mô nhỏ hơn. Các mẫu bán tự động cung cấp sự cân bằng giữa chi phí và chức năng, làm cho chúng trở nên lý tưởng cho sản xuất quy mô trung bình. Các máy hoàn toàn tự động, mặc dù đắt hơn, mang lại hiệu suất và độ chính xác không thể sánh kịp cho các công việc có khối lượng lớn.

Xem xét lợi ích lâu dài của khoản đầu tư của bạn. Chi phí ban đầu cao hơn có thể giúp bạn tiết kiệm thời gian và chi phí lao động trong tương lai. Đánh giá nhu cầu sản xuất của bạn và xác định xem khả năng của máy có xứng đáng với giá của nó hay không. Luôn hướng tới việc đạt được sự cân bằng giữa khả năng chi trả và chất lượng để đảm bảo bạn nhận được giá trị tốt nhất cho số tiền của mình.

Kích thước và Công suất của Máy

Kích thước và công suất của máy ảnh hưởng trực tiếp đến khả năng sử dụng và hiệu quả của nó. Các máy nhỏ gọn hoạt động tốt trong không gian nhỏ hoặc cho việc sử dụng thỉnh thoảng. Các máy lớn hơn, được thiết kế cho mục đích công nghiệp, xử lý sản xuất hàng loạt một cách dễ dàng. Đánh giá không gian có sẵn trong nơi làm việc của bạn và chọn một máy phù hợp mà không làm giảm chức năng.

Công suất đề cập đến khả năng của máy trong việc xử lý các loại vải có chiều rộng và độ dày khác nhau. Một số máy có thể xử lý các loại vải nhẹ, trong khi những máy khác được thiết kế cho các vật liệu nặng như rèm cửa hoặc bọc. Đảm bảo rằng máy bạn chọn có thể quản lý các loại rèm mà bạn dự định sản xuất. Sự không phù hợp về công suất có thể dẫn đến sự không hiệu quả hoặc hư hại cho vải.

Các kiểu nếp gấp và tính linh hoạt

Tính linh hoạt của máy nếp gấp rèm xác định khả năng thích ứng của nó với các kiểu nếp gấp khác nhau. Một số máy chuyên về các nếp gấp cụ thể, chẳng hạn như nếp gấp kẹp hoặc nếp gấp hộp, trong khi những máy khác cung cấp các cài đặt điều chỉnh cho nhiều kiểu khác nhau. Nếu bạn làm việc trên nhiều dự án đa dạng, hãy ưu tiên một máy hỗ trợ nhiều tùy chọn nếp gấp.

Tính linh hoạt cũng mở rộng đến khả năng tương thích với vải. Các máy xử lý các loại vật liệu khác nhau, từ vải mỏng nhẹ đến vải dày, cung cấp sự linh hoạt lớn hơn. Hãy tìm kiếm các tính năng như độ sâu và khoảng cách nếp gấp có thể điều chỉnh để tùy chỉnh thiết kế theo sở thích của bạn. Một chiếc máy linh hoạt không chỉ nâng cao sự sáng tạo mà còn đảm bảo bạn có thể đáp ứng những yêu cầu độc đáo của khách hàng.

Việc bảo trì và bền

Bảo trì đúng cách đảm bảo máy gấp rèm của bạn hoạt động hiệu quả và kéo dài trong nhiều năm. Bỏ bê việc bảo trì có thể dẫn đến các vấn đề về hiệu suất và sửa chữa tốn kém. Bằng cách tuân theo một vài thực hành thiết yếu, bạn có thể duy trì độ bền của máy và giữ cho nó ở trạng thái tối ưu.

Bằng cách kết hợp những thực hành này, bạn bảo vệ khoản đầu tư của mình và đảm bảo máy cung cấp kết quả nhất quán, chất lượng cao. Một chiếc máy gấp rèm được bảo trì tốt không chỉ nâng cao năng suất mà còn giúp bạn tránh được những chi phí bất ngờ.

Mẹo bảo trì và kéo dài tuổi thọ

Dọn dẹp định kỳ

Giữ cho máy xếp nếp rèm của bạn sạch sẽ là điều cần thiết để duy trì hiệu suất của nó. Bụi, sợi vải và mảnh vụn có thể tích tụ trong các bộ phận của máy, gây ra sự không hiệu quả hoặc thậm chí hư hỏng. Sau mỗi lần sử dụng, hãy dành vài phút để loại bỏ bất kỳ cặn bẩn nào. Sử dụng bàn chải mềm hoặc khí nén để làm sạch những khu vực khó tiếp cận như con lăn, kẹp và cơ chế xếp nếp. Chú ý đặc biệt đến các bộ phận chuyển động, vì đây là những bộ phận dễ bị tích tụ nhất. Việc làm sạch thường xuyên không chỉ đảm bảo hoạt động trơn tru mà còn kéo dài tuổi thọ của máy bạn.

Bôi trơn và hiệu chuẩn

Bôi trơn đóng vai trò quan trọng trong việc giảm ma sát giữa các bộ phận chuyển động. Nếu không có bôi trơn đúng cách, máy của bạn có thể gặp phải sự hao mòn, dẫn đến hỏng hóc cơ khí. Kiểm tra hướng dẫn của nhà sản xuất để biết loại chất bôi trơn được khuyến nghị. Áp dụng một cách tiết kiệm vào các bánh răng, khớp nối và các bộ phận chuyển động khác. Bôi trơn quá mức có thể thu hút bụi, vì vậy chỉ sử dụng lượng được chỉ định.

Hiệu chuẩn đảm bảo rằng máy của bạn tạo ra các nếp gấp chính xác mỗi lần. Theo thời gian, việc sử dụng thường xuyên có thể khiến các cài đặt bị thay đổi, dẫn đến kích thước nếp gấp không đồng nhất. Hãy kiểm tra máy định kỳ với một mẫu vải để kiểm tra sự căn chỉnh và độ chính xác. Nếu bạn nhận thấy có sự bất thường, hãy điều chỉnh các cài đặt theo hướng dẫn sử dụng. Hiệu chuẩn định kỳ giúp máy của bạn hoạt động ở mức tốt nhất.

Dịch vụ chuyên nghiệp

Bảo trì định kỳ là rất cần thiết, nhưng dịch vụ chuyên nghiệp cũng cần thiết để đảm bảo độ bền của máy. Các kỹ thuật viên có thể phát hiện các vấn đề tiềm ẩn và thực hiện các kiểm tra và thay thế cần thiết để giữ cho máy của bạn an toàn và hoạt động. Dịch vụ hàng năm giúp giảm thời gian ngừng hoạt động và tránh các sửa chữa tốn kém.

Chọn một nhà cung cấp dịch vụ được ủy quyền bởi nhà sản xuất để đảm bảo các bộ phận chính hãng và quy trình đúng được sử dụng. Giữ một nhật ký bảo trì để theo dõi lịch sử của máy móc của bạn. Bảo trì đúng cách đảm bảo hiệu suất ổn định và tiết kiệm chi phí lâu dài. Hãy chăm sóc thiết bị của bạn để hỗ trợ các dự án của bạn theo thời gian.

Máy xếp nếp rèm cung cấp một cách hiệu quả để đạt được những nếp gấp chất lượng chuyên nghiệp với độ chính xác. Bằng cách hiểu cách hoạt động của những máy này và đánh giá lợi ích của chúng, bạn có thể chọn loại phù hợp để đáp ứng nhu cầu cụ thể của mình. Dù bạn ưu tiên điều khiển thủ công hay tự động hóa tiên tiến, những máy này nâng cao năng suất và mang lại kết quả nhất quán. Bảo trì định kỳ đảm bảo tuổi thọ và hiệu suất tối ưu của chúng, bảo vệ khoản đầu tư của bạn. Với máy móc phù hợp và sự chăm sóc đúng cách, bạn có thể nâng cao các dự án làm rèm của mình lên tiêu chuẩn chuyên nghiệp.