flyscreen pleating machine factory

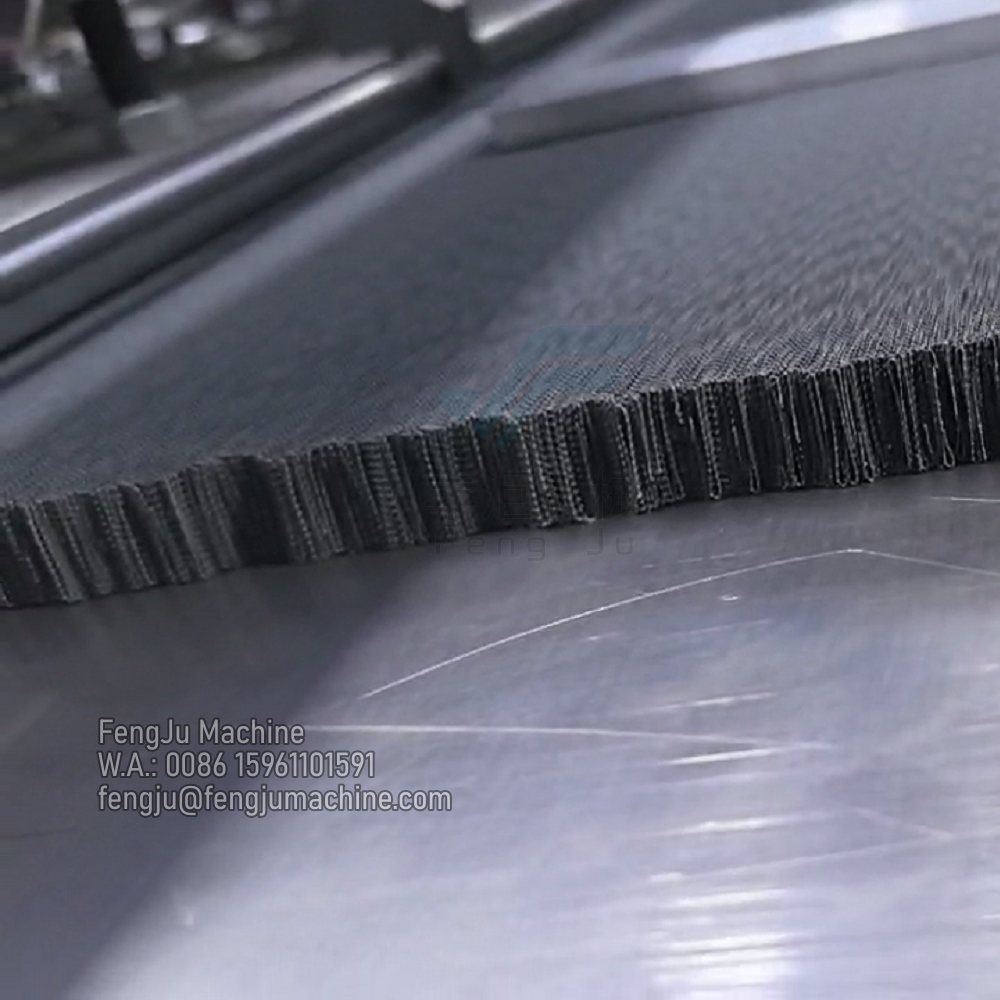

A flyscreen pleating machine factory represents a state-of-the-art manufacturing facility dedicated to producing precision equipment for the window screening industry. These specialized facilities integrate advanced automation systems and quality control measures to create machines that efficiently pleat and process window screening materials. The factory's core capabilities include the production of high-speed pleating systems capable of handling various mesh materials, including fiberglass, aluminum, and synthetic fabrics. The manufacturing process incorporates cutting-edge CNC technology, robotic assembly lines, and sophisticated testing facilities to ensure each machine meets strict quality standards. The factory's production line is designed to accommodate both standard and custom pleating machine specifications, offering solutions for different production volumes and screening applications. Key technological features include digital control systems for precise pleat formation, automated material feeding mechanisms, and integrated quality inspection systems. The facility also maintains dedicated research and development departments focused on improving machine efficiency and developing new pleating technologies. These factories serve various sectors, including window manufacturers, screening companies, and construction suppliers, providing essential equipment for producing pleated window screens, door screens, and specialized filtering applications. The comprehensive facility typically includes assembly areas, testing zones, parts warehousing, and technical support centers, ensuring complete product lifecycle management from conception to after-sales service.