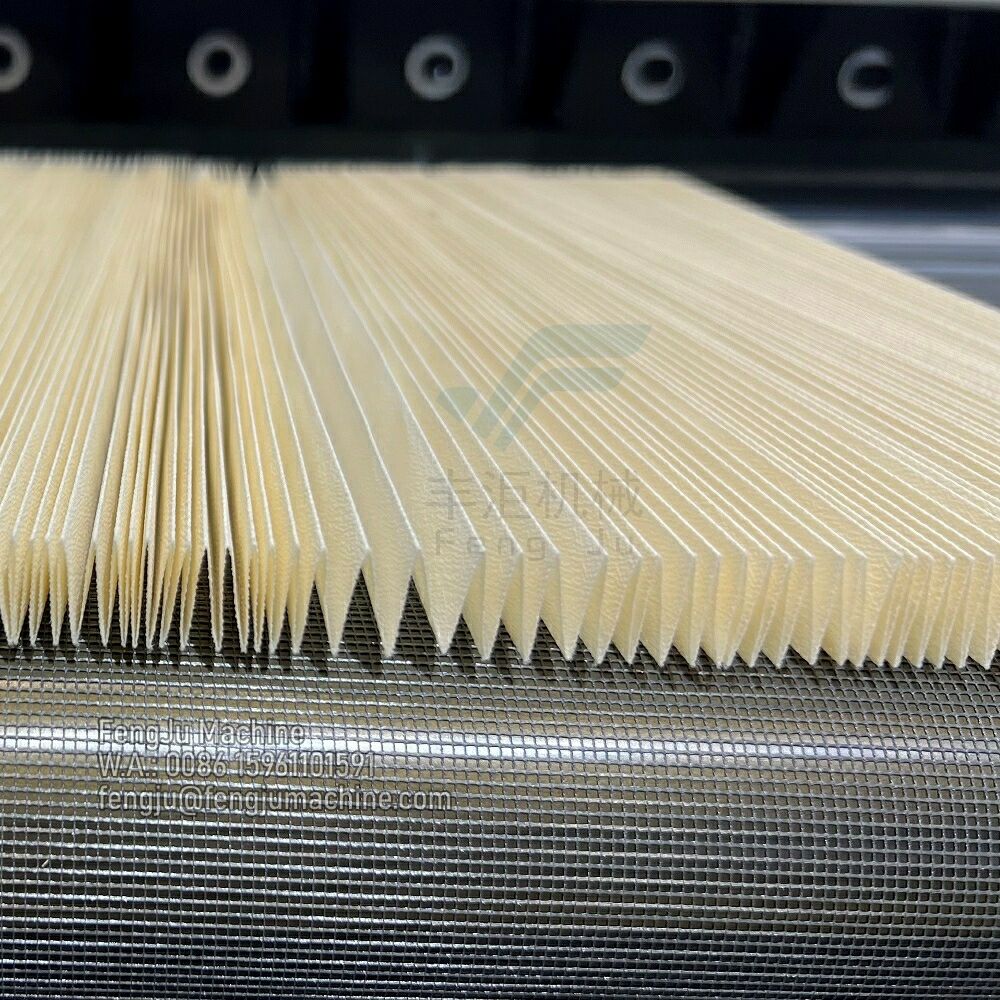

knife type pleating machine

The knife type pleating machine is a sophisticated piece of equipment designed for precision pleating in various industrial applications. Its main functions include the consistent and accurate creation of pleats in materials such as filter media, paper, and fabrics. Technological features of this machine encompass a set of sharp knives that pleat the material by cutting and folding it in a uniform pattern, which is then held together by adhesive or thermal processes. The machine typically features an automated control system that allows operators to customize pleat sizes, depths, and spacing according to specific project requirements. Applications of the knife type pleating machine range from the manufacturing of air and oil filters to the creation of intricate pleated materials for fashion and home decor.