screen pleating machine

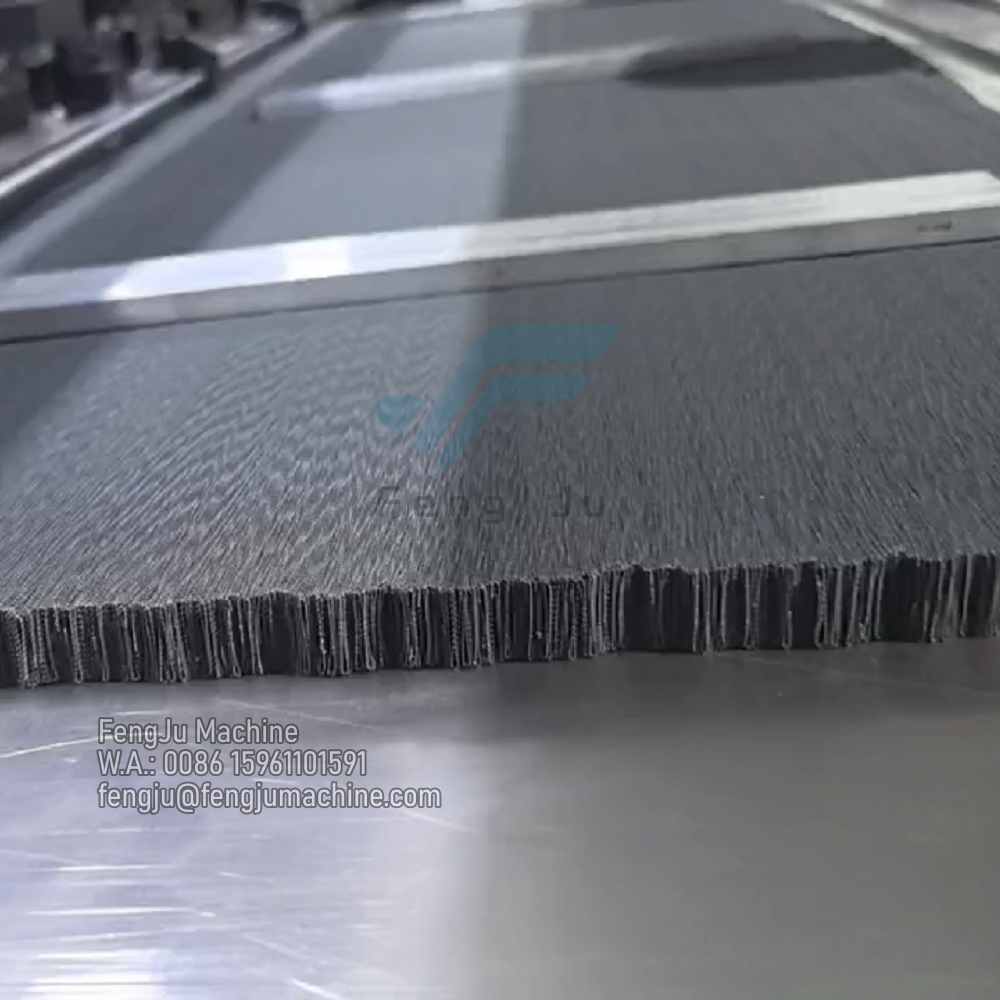

The screen pleating machine is a sophisticated piece of equipment designed to fold or pleat screens with precision and speed. Its main functions include the automated pleating of various materials used in filtration, separation, and other industrial processes. Technological features such as programmable control systems, touch screen interfaces, and advanced motor technologies ensure that the machine operates with high efficiency and minimal human intervention. The applications of the screen pleating machine are vast, ranging from manufacturing air filters and fuel filters to medical devices and separators in chemical processing. This machine streamlines the production process, offering consistent quality and high output, which is crucial in maintaining competitiveness in the market.