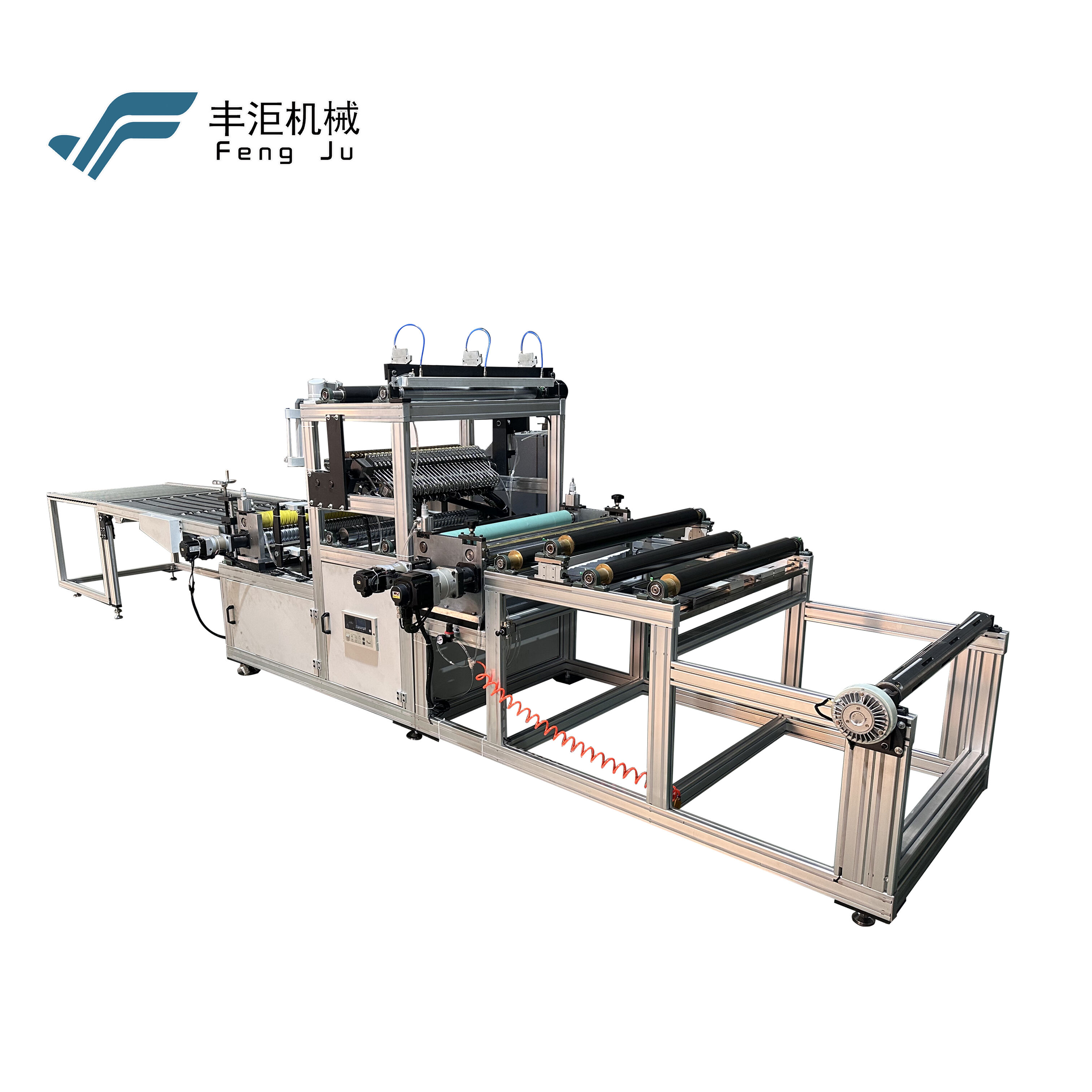

plisēto žalūziju mašīna

Plīšu žalūziju mašīna ir jaunākās paaudzes risinājums loga aiztērējumu ražošanā, apvienojot precīzu inženieriju ar automatizētu efektivitāti. Šis sarežģītais aprīkojums optimizē plīšu žalūziju ražošanu, ietverot vairākas integrētas darbības, tostarp auduma plīšanas, auklas ievietošanas un komponentu montāžas procesus. Mašīna izmanto modernu servopiedziņu tehnoloģiju, lai nodrošinātu vienmērīgus plīšu rakstus un precīzus izmērus, uzturējot kvalitātes standartus lielapjomu ražošanas ciklos. Tās datorizētā vadības sistēma ļauj operatoriem programmēt konkrētus plīšu izmērus, atstatumus un rakstus, pielāgojoties dažādiem auduma veidiem un dizaina prasībām. Mašīnai ir vairākas apstrādes stacijas, kas nodrošina dažādas ražošanas fāzes — sākot no auduma padodam līdz galaprodukta iepakošanai, ievērojami samazinot nepieciešamību pēc manuālā darba. Izgatavota no rūpnieciskās klases komponentiem, plīšu žalūziju mašīna var nepārtraukti darboties ražošanas vidē, apstrādājot materiālus ātrumā līdz pat 40 metriem stundā. Sistēmā iekļauti automātiski kvalitātes kontroles mehānismi, kas uzrauga plīšanas precizitāti un materiāla novietojumu visā ražošanas procesā, minimizējot atkritumus un nodrošinot vienmērīgu produkta kvalitāti. Šis aprīkojums ir īpaši vērtīgs ražotājiem, kuri cenšas paplašināt savas ražošanas iespējas, vienlaikus saglabājot precīzu amata meistarību plīšu žalūziju ražošanā.