multi pleat machine

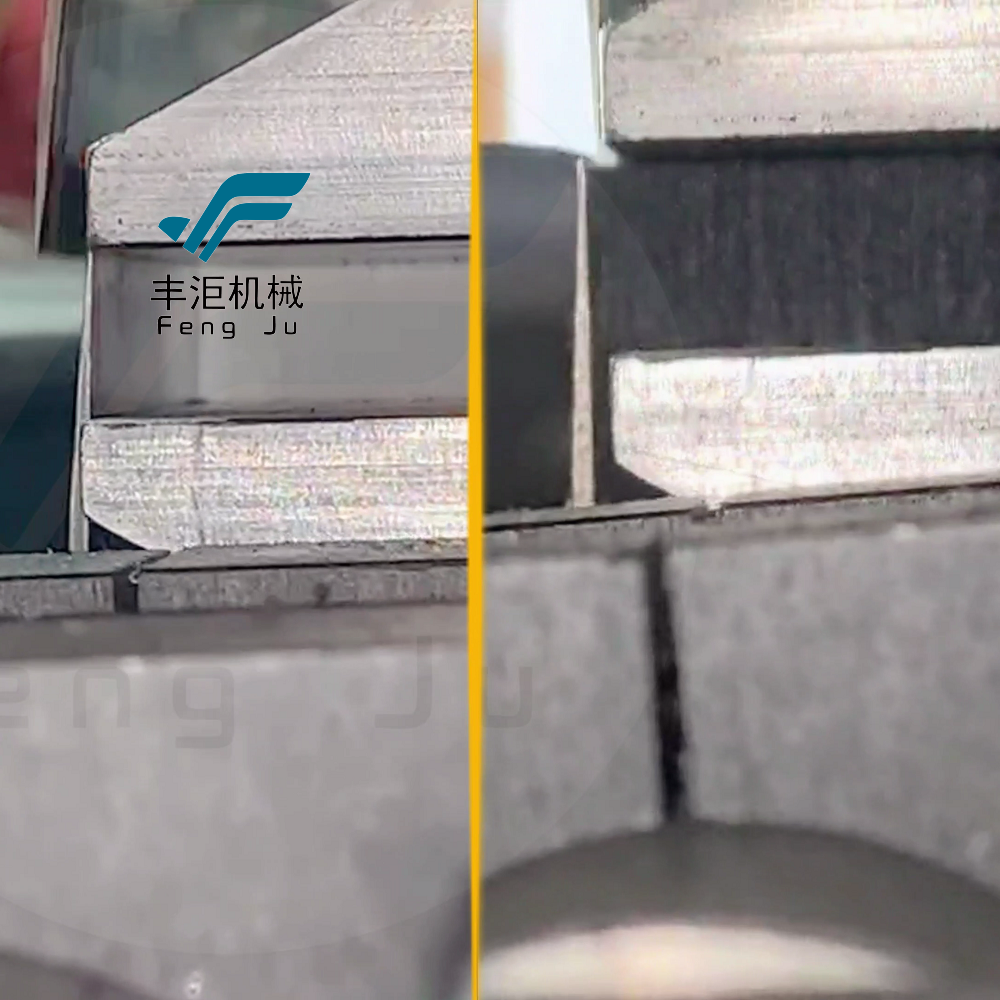

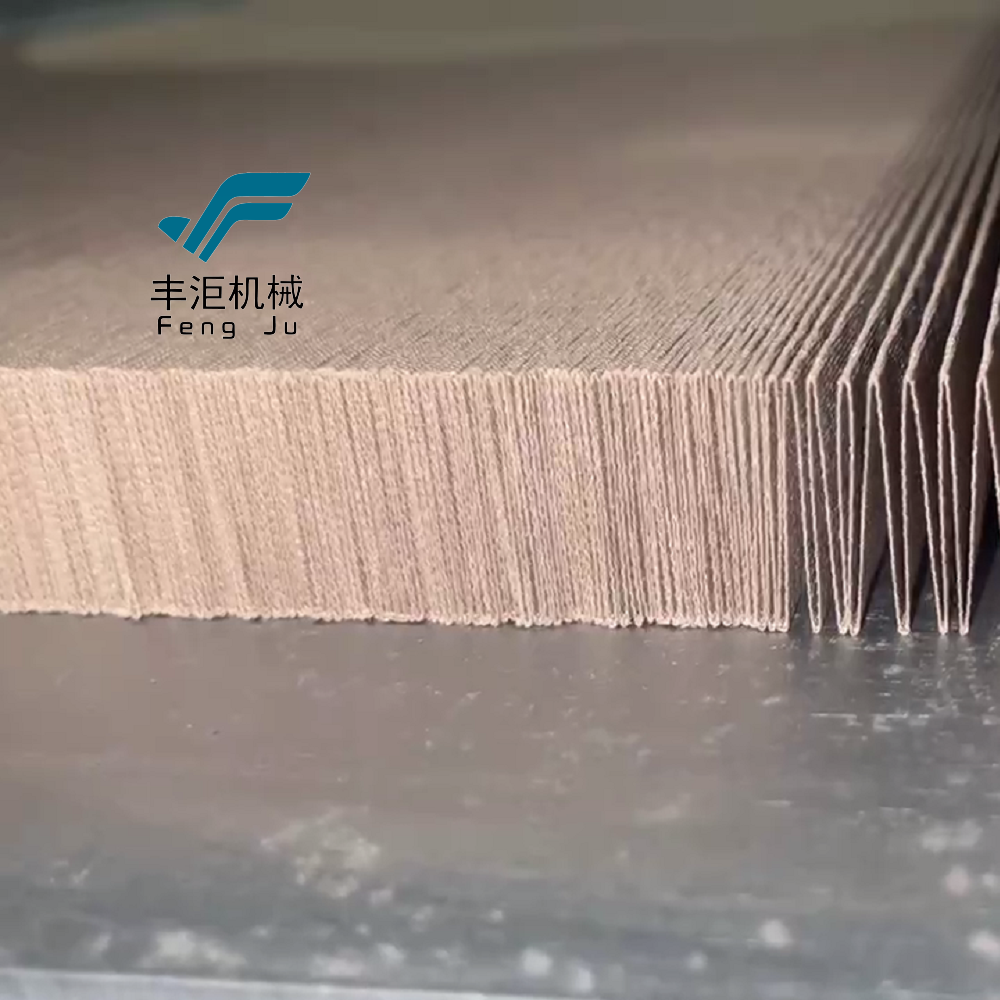

The multiple pleat machine is a sophisticated piece of industrial equipment designed to efficiently create precision folds in a variety of materials, most commonly used in the filtration and automotive industries. This machine's main functions include pleating materials to increase their surface area, enhance filtration capabilities, and to fit into specific assembly designs. Technological features include programmable control systems for custom fold patterns, automated material feeding, and precision sensors that ensure consistent pleat quality. The applications of the multi pleat machine are extensive, from manufacturing air and oil filters to creating components for automotive and aerospace industries where high-performance materials require intricate folds for compact assembly and maximum efficiency.