pleating machine with hotmelt

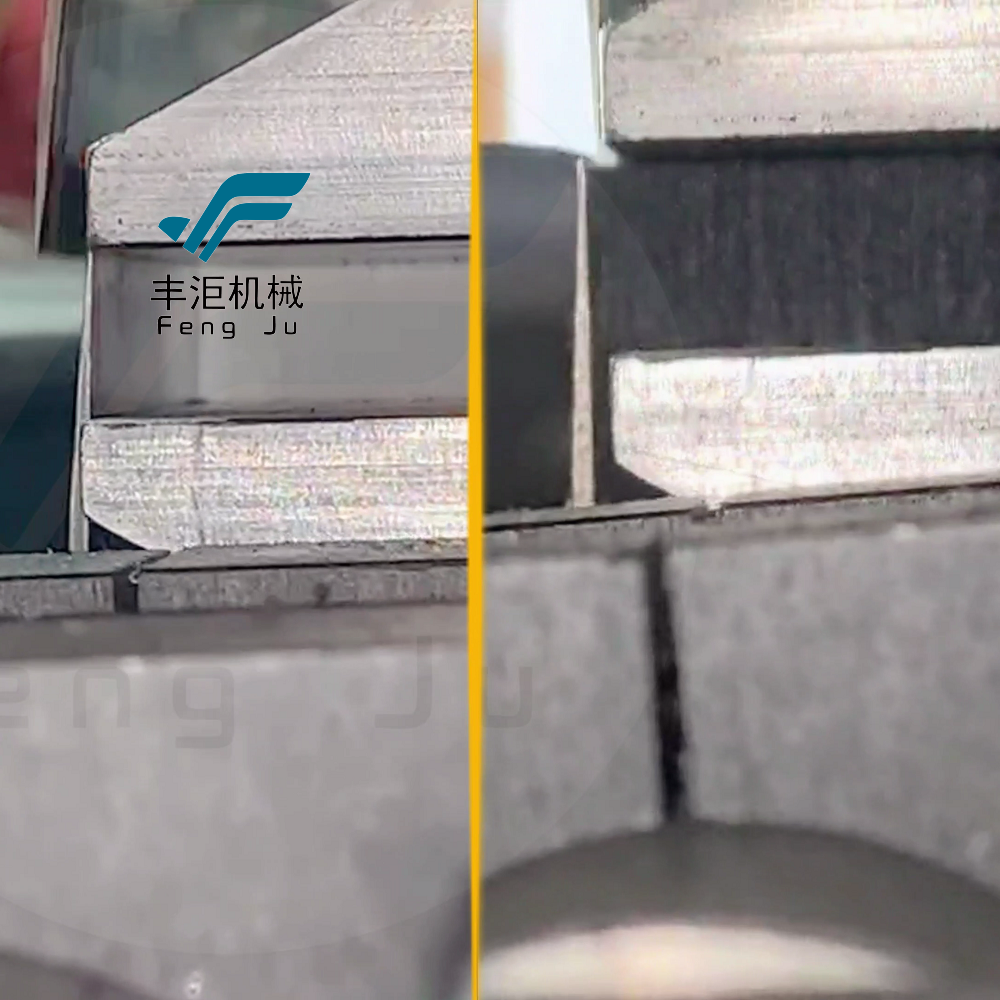

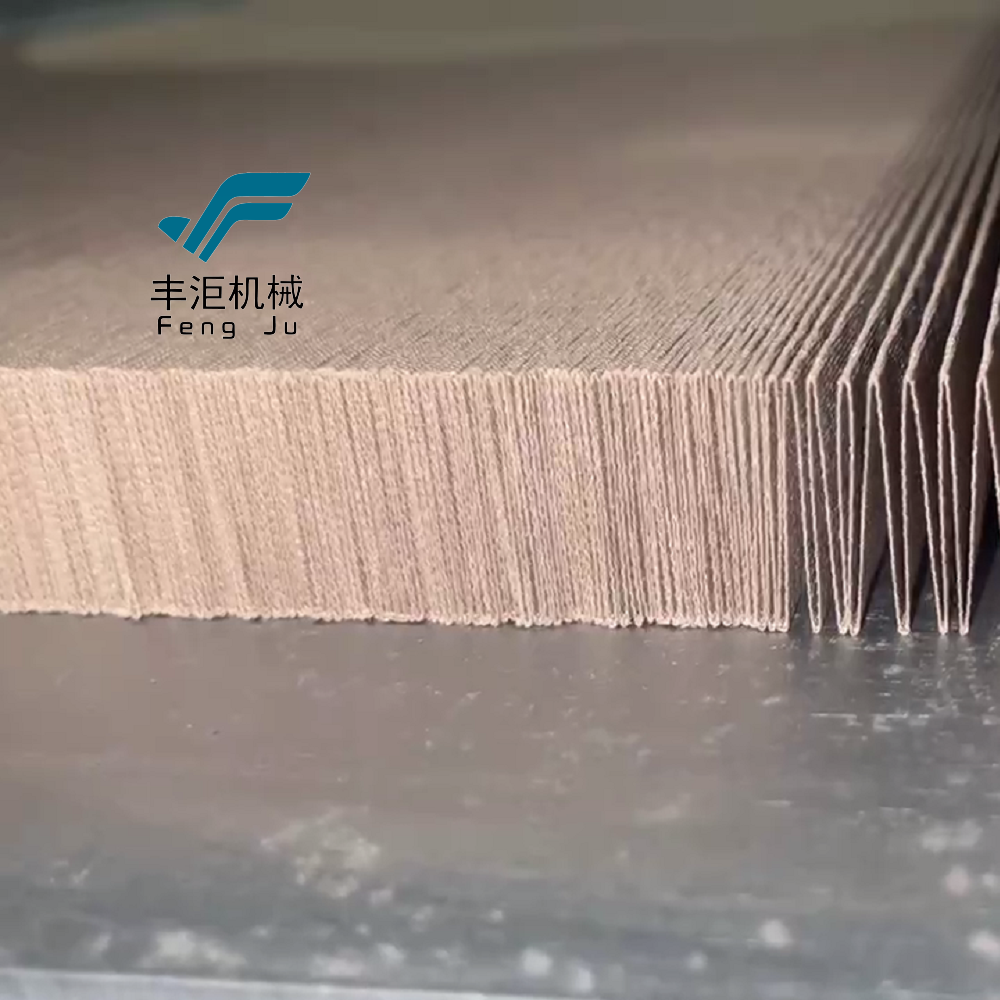

The pleating machine with hotmelt is a sophisticated piece of equipment designed for efficient and precise pleating of materials in various industries. Its main functions include the continuous pleating of fabrics, papers, and other materials while simultaneously applying a hotmelt adhesive for secure bonding. Technological features of this machine include an advanced control system for precision pleating, variable speed settings for different material types, and a hotmelt application system that ensures consistent adhesive distribution. This machine finds its applications in filtration, automotive, and apparel industries, where pleated materials are integral components.